How WRS Technology Transforms Efficiency in Industrial Cleaning

November 19, 2024

Summary: This article explores how Kaijo’s Water Resonance System (WRS) technology transforms industrial ultrasonic cleaning by enhancing cleaning efficacy, improving production efficiency, reducing costs, and addressing critical challenges manufacturing engineers face across various industries and applications.

In modern manufacturing, precision and cleanliness are paramount. Effective industrial cleaning solutions have become critical as production demands intensify and tolerances tighten. Kaijo’s Water Resonance System (WRS) technology emerges as a significant innovation in industrial ultrasonic cleaners, promising to redefine cleaning standards across the industry.

For manufacturing engineers focused on operational excellence and lean principles, understanding WRS technology’s potential is crucial. This advanced approach to industrial cleaning addresses common challenges in manufacturing processes, from efficiency bottlenecks to quality control issues.

Understanding WRS Technology

Kaijo’s Water Resonance System (WRS) represents a groundbreaking advancement in industrial ultrasonic cleaners. This innovative technology addresses common challenges in ultrasonic cleaning by optimizing the distribution of ultrasonic energy throughout the cleaning bath, resulting in more efficient and uniform cleaning action.

The core principle behind WRS is its ability to condition the water, improving bubble formation and distribution throughout the entire cleaning tank rather than concentrating over the transducer as in conventional systems. This leads to several key improvements:

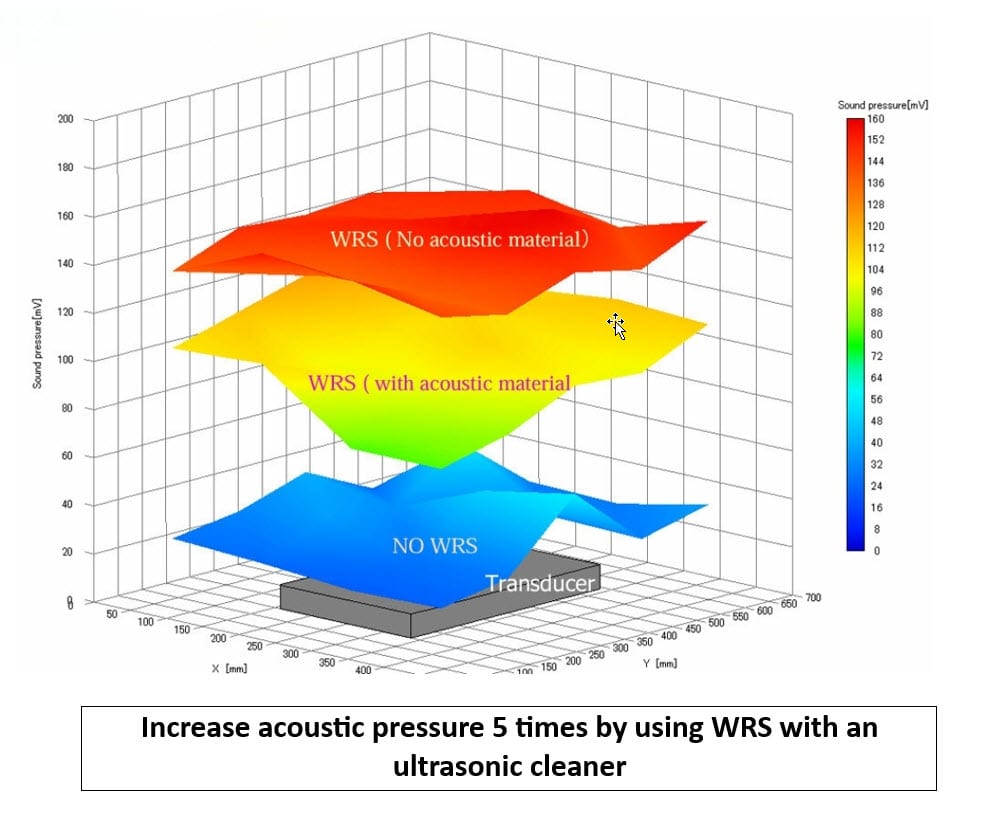

- Enhanced Cavitation: WRS increases the acoustic pressure of ultrasonic waves in the bath up to five times, resulting in more robust and uniform cleaning.

- Optimized Bubble Formation: The system treats dissolved gases and optimizes the production of nuclei that generate cavitation bubbles, ensuring even distribution and more effective cleaning.

- Three-Dimensional Cleaning: WRS facilitates cleaning inside objects such as cylinders where standard ultrasonic waves might not fully reach.

- Versatility: The technology is suitable for cleaning various materials, including HDD components, metal, and glass parts.

Key features of the Water Resonance System include:

- 5 times greater sound pressure than conventional models, improving cleaning efficiency

• Reduced operational noise

• Uniform ultrasonic wave distribution for optimum cleaning

• Less erosion and longer product lifetime (3 to 10 times longer than conventional models)

• Heat-resistant temperature at the transducer part up to 100°C

WRS technology is available in different models to accommodate various temperature ranges, power requirements, and liquid capacities. It’s compatible with various cleaning liquids, including city water, pure water, ionic water, and deionized water.

For manufacturing engineers focused on optimizing processes and maintaining high product quality, WRS technology offers a compelling solution that aligns perfectly with lean manufacturing principles. Its ability to clean more effectively while using less energy and reducing the risk of component damage makes it an ideal choice for modern manufacturing environments, especially those dealing with challenging cleaning applications or seeking to reduce reliance on harsh chemicals.

Applications of WRS Technology in Industrial Cleaning

Kaijo’s Water Resonance System (WRS) technology demonstrates remarkable versatility across various industrial materials and cleaning scenarios. Its enhanced cleaning efficacy and gentle operation make it suitable for various applications that have traditionally challenged conventional ultrasonic cleaners.

- Hard Disk Drive (HDD) Components:

WRS excels in cleaning delicate HDD parts, ensuring thorough cleaning without risking damage. The uniform distribution of ultrasonic waves meets the high standards required in the data storage industry. - Metal Parts:

For complex metal components, WRS offers superior cleaning capabilities. Enhanced cavitation intensity reaches into crevices and blind holes often missed by traditional methods, making it ideal for automotive and aerospace industries. - Glass Components:

The gentle yet thorough nature of WRS makes it perfect for cleaning sensitive glass components without scratching or etching, which is crucial in optics and solar panel manufacturing. - Electronic Components:

WRS’s ability to clean effectively at lower power settings makes it suitable for delicate electronic components, removing contaminants without risking damage to sensitive circuitry. - Medical Devices:

WRS provides the thorough cleaning required for complex devices and surgical instruments in the medical industry, where cleanliness standards are exceptionally high. - Precision Manufacturing:

For industries requiring ultra-clean surfaces, such as semiconductor manufacturing, WRS offers the cleanliness needed for optimal performance and yield. - Challenging Contaminants:

WRS has effectively removed stubborn contaminants resistant to conventional cleaning methods, sometimes eliminating the need for hazardous chemical processes.

The versatility of WRS is further enhanced by its compatibility with various cleaning liquids, including city water, pure water, ionic water, and deionized water. This flexibility allows manufacturers to tailor the cleaning process to their specific needs and materials.

In addition, WRS’s ability to clean inside objects such as cylinders, where standard ultrasonic waves might not fully reach, opens up new possibilities for cleaning complex geometries and internal structures.

For manufacturing engineers dealing with diverse materials and challenging cleaning requirements, WRS offers a robust, adaptable solution that aligns with quality assurance goals and environmental sustainability initiatives.

Enhancing Cleaning Efficacy for Manufacturing Processes

Kaijo’s Water Resonance System (WRS) technology significantly improves the performance of industrial ultrasonic cleaners, addressing critical challenges manufacturing engineers face. Below are ways the WRS technology enhances cleaning efficacy and contributes to overall manufacturing excellence:

Improved Cleaning Precision:

- WRS achieves cleanliness levels that meet or exceed stringent industry standards.

• Uniform distribution of smaller bubbles ensures consistent cleaning across all surfaces, including complex geometries.

• Enhanced cavitation intensity allows for thorough cleaning without increasing the risk of damage to delicate components.

Increased Production Efficiency:

- Faster, more effective cleaning cycles reduce downtime and increase throughput.

• WRS can clean inside objects like cylinders where standard ultrasonic waves might not fully reach, eliminating additional cleaning steps.

• Versatility in handling various materials and contaminants streamlines cleaning processes across different product lines.

Cost Reduction:

- Minimized need for harsh chemicals leads to significant cost savings over time.

• Reduced energy consumption due to more efficient cleaning processes and lower operational costs.

• Longer equipment lifespan (3 to 10 times longer than conventional models) reduces replacement and maintenance expenses.

Enhanced Product Quality:

- Consistent, high-level cleaning maintains stringent quality standards across production batches.

• Reduced chemical use minimizes the risk of residue on cleaned parts, ensuring higher product purity.

• Improved cleaning of complex parts improves final product performance and reliability.

Environmental and Safety Benefits:

- Decreased use of harsh chemicals improves workplace safety and reduces environmental impact.

• Lower operational noise contributes to a better working environment.

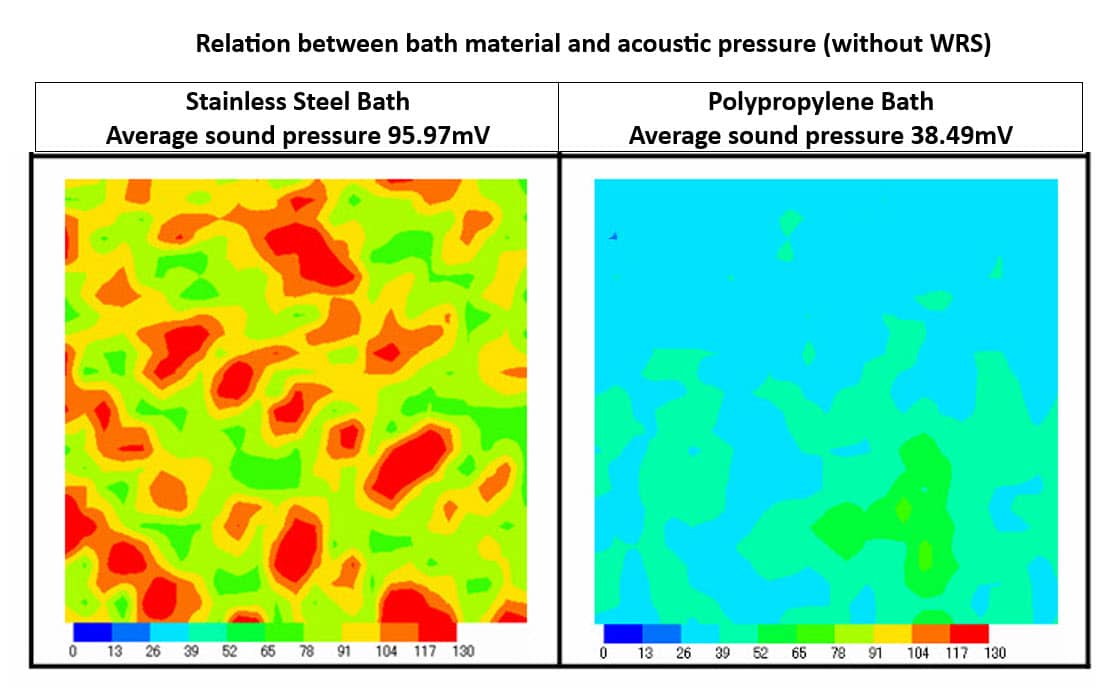

Relationship between Bath Material and Acoustic Pressure (without WRS)

- Stainless Steel Bath: The average acoustic pressure recorded is 95.97mV

- Polypropylene Bath: The average acoustic pressure recorded is 38.49mV

Quantifiable Improvements:

- Research indicates a fivefold increase in acoustic pressure within the cleaning bath when utilizing a WRS system in conjunction with an ultrasonic cleaner, compared to using the ultrasonic cleaner alone.

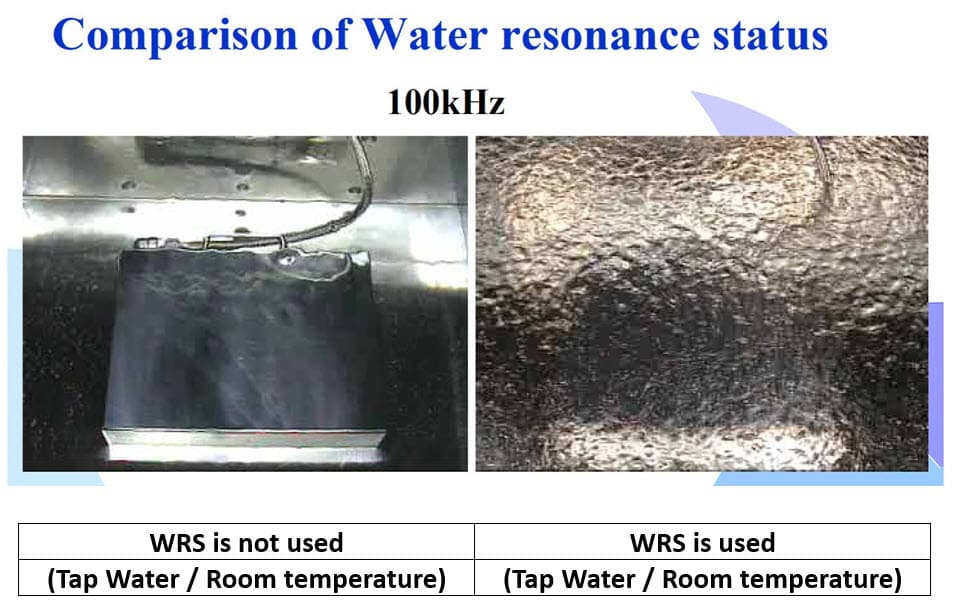

- Visual evidence demonstrates more dynamic and turbulent cleaning action, indicating enhanced cavitation energy.

For manufacturing engineers focused on lean principles and continuous improvement, these benefits make WRS technology an attractive option for industrial cleaning needs. Its ability to enhance cleaning efficacy while simultaneously reducing costs, improving product quality, and supporting sustainability initiatives aligns perfectly with the goals of modern manufacturing environments.

Advantages for Manufacturing Engineers

Kaijo’s Water Resonance System (WRS) technology aligns perfectly with the goals of modern manufacturing engineers, offering solutions that address critical challenges in industrial cleaning processes.

- Lean Manufacturing Support:

WRS reduces waste by minimizing the use of chemicals and improving energy efficiency.

• Faster cleaning cycles and reduced downtime contribute to streamlined production processes.

• Consistent cleaning results reduce the need for rework, aligning with lean principles. - Quality Assurance Enhancement:

Uniform cleaning across all surfaces ensures consistent product quality.

• The ability to clean complex geometries and internal structures improves overall part cleanliness.

• Reduced reliance on harsh chemicals minimizes the risk of residue-related quality issues. - Process Integration:

WRS can be seamlessly integrated into existing manufacturing processes, minimizing disruption during implementation.

• The system’s versatility allows it to be used with various cleaning liquids and part materials, adapting to different production needs. - Troubleshooting Support:

WRS provides more consistent cleaning results, reducing variables in quality control processes.

• The system’s ability to clean challenging contaminants can help resolve persistent cleanliness issues. - Cost-Effectiveness:

Reduced energy consumption and chemical use lead to lower operational costs.

• Longer equipment lifespan (3-10 times longer than conventional models) reduces replacement and maintenance expenses. - Environmental and Safety Benefits:

Decreased use of harsh chemicals improves workplace safety and reduces environmental impact.

• Lower operational noise contributes to a better working environment. - Adaptability to Future Needs:

WRS’s advanced technology positions manufacturers to meet increasingly stringent cleanliness standards.

• The system’s flexibility allows for adaptation to new materials and cleaning challenges as they emerge.

These advantages make WRS ideal for manufacturing engineers looking to stay competitive in an increasingly demanding industry. By addressing current needs and future challenges, WRS technology provides a forward-thinking solution for industrial cleaning processes.

Choosing the Right Ultrasonic Cleaning Solution

When evaluating industrial ultrasonic cleaners and manufacturers, consider these critical factors in selecting the most effective solution for your needs:

Technology Innovation:

Look for manufacturers investing in cutting-edge technologies like Kaijo’s Water Resonance System (WRS), which offers:

- Up to 5 times greater sound pressure for improved cleaning efficiency

• Uniform ultrasonic wave distribution

• Reduced operational noise and longer equipment lifespan

Customization Options:

Ensure the solution can be tailored to your specific requirements:

- Compatibility with various cleaning liquids

• Models for different temperature ranges and liquid capacities

• Adaptability to clean complex geometries

Support and Service:

Choose a provider offering comprehensive support:

- Expert guidance in system selection

• Ongoing technical support and training

• Customizable maintenance plans

Proven Track Record:

Seek manufacturers with success in your industry. Kaijo has expertise in:

- HDD component cleaning

• Metal and glass part processing

• Precision manufacturing for electronics and medical devices

Integration Capabilities:

Consider how easily the system integrates into existing processes:

- Compatibility with current ultrasonic cleaning systems

• Options for inline and once-through models

Environmental and Safety Considerations:

Evaluate the system’s ability to:

- Reduce reliance on harsh chemicals

• Improve workplace safety

• Lower energy consumption

By carefully considering these factors, you can select an industrial ultrasonic cleaning solution that meets current needs and prepares your manufacturing process for future challenges. Kaijo’s WRS technology, with its advanced features and proven performance, stands out as a strong contender for manufacturing engineers seeking top-tier cleaning solutions.

Conclusion: Revolutionizing Industrial Cleaning with WRS Technology

As industries continue to demand higher cleanliness and efficiency standards, Kaijo’s Water Resonance System (WRS) stands out as a transformative solution in industrial ultrasonic cleaners. By addressing key challenges in manufacturing processes, WRS technology offers a path to enhanced productivity, cost reduction, and superior product quality.

The benefits of WRS include:

- Improved cleaning precision and uniformity

- Increased production efficiency

- Significant cost savings through reduced energy and chemical use

- Enhanced product quality and reliability

- Adaptability to diverse materials and contaminants

For manufacturing engineers committed to lean principles and continuous improvement, WRS technology represents an opportunity to revolutionize cleaning processes and gain a competitive edge in the market.

As you consider upgrading your industrial cleaning capabilities, explore the full potential of Kaijo’s WRS technology. Its ability to meet current demands while preparing for future challenges makes it an invaluable asset in modern manufacturing environments. To discover how WRS can transform your specific cleaning processes and address your unique manufacturing challenges, contact Kaijo for a free consultation today.