Kaijo’s New Phenix+ Ultrasonic Generator Optimizes Cleaning Performance

April 29, 2019

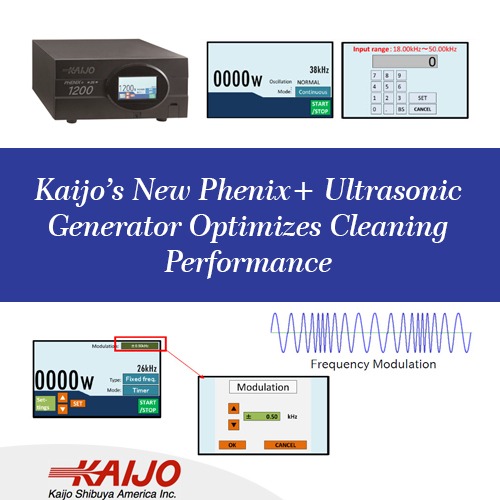

Ultrasonic generators produce the high-frequency electrical signal that powers the ultrasonic transducers immersed in the cleaning solution. The transducers are passive in the sense that they merely convert the electrical signal into sound waves. The generator handles all the control functions and is responsible for determining the frequencies used, the power output and the frequency modulation. The new Kaijo Phenix+ industrial ultrasonic generator improves these functions and supports a more even, more efficient cleaning performance.

Ultrasonic generators produce the high-frequency electrical signal that powers the ultrasonic transducers immersed in the cleaning solution. The transducers are passive in the sense that they merely convert the electrical signal into sound waves. The generator handles all the control functions and is responsible for determining the frequencies used, the power output and the frequency modulation. The new Kaijo Phenix+ industrial ultrasonic generator improves these functions and supports a more even, more efficient cleaning performance.

The Phenix+ Ultrasonic Generator Harnesses the Latest Technology

When designing the Phenix+ ultrasonic generator, Kaijo analyzed possible sources of problems with ultrasonic generators in the industry and included features that make the unit easier to use, more efficient and offering better control of the ultrasonic cleaning system functions. New features include the following:

- Touch screen for an easy-to-use operator interface.

- Improved power output monitoring and control.

- Advanced automatic tuning for changed process conditions or a changed transducer.

- A standard frequency modulation mode.

- More efficient cooling of the generator unit.

- Reduced power use due to a more efficient power circuit.

These improvements make the Phenix+ ultrasonic generator an ideal source for the high-frequency electrical signal required for an ultrasonic cleaning system. Operators can make use of the additional functions to control the cleaning process more precisely and deliver improved cleaning performance.

The Touch Panel Controls Operations and Displays Conditions

Operators can use the touch panel to start and stop the ultrasonic cleaning system and to select the mode of operation. A numeric keypad allows them to enter the set points for frequencies and power. The panel displays the output power and the operating frequency. When errors or alarms occur, the panel displays the error or alarm and a descriptive text with additional instructions. The panel represents an intuitive user interface that does not require extensive training.

Automatic Adjustment for Changes in the Cleaning Environment or the Transducer

The automatic tuning function of the Phenix+ keeps the output in tune with the selected set points and the characteristics of the cleaning solution. During the cleaning process, the cleaning environment may vary. The temperature of the cleaning solution may change, or some solution might evaporate, changing the depth. The operator could change the type of cleaning solution or change the transducer for another one of the same type. In all these cases, the characteristics of the cleaning environment will have changed, and the operation of the ultrasonic generator has to be adjusted.

The generator monitors the impedance of the transducer as a function of the frequency. Changes in the cleaning environment or a change of transducer can affect the impedance. When such a change is detected, the generator adjusts its operation to keep the cleaning performance at an optimal level.

Frequency Modulation Ensures a Uniform Ultrasonic Wave Distribution

When an ultrasonic generator operates at a fixed single frequency, the geometries of the cleaning tanks and the parts to be cleaned create dead spots and hot spots where the ultrasonic waves are absent or especially concentrated. By modulating the frequency around a central value, these effects are reduced because the sound wavelengths are no longer fixed. The ultrasonic wave distribution is more uniform and cleaning performance is even.

The Phenix+ allows the operator to select the bandwidth within which the frequency is modulated. If the operator observes uneven cleaning, the amount of frequency modulation can be increased, and this feature is a standard function in all new Phenix+ units.

Increased Efficiency Reduces Cooling Requirements

The new Phenix+ industrial ultrasonic generator has a more efficient power circuit and the cooling fan only runs when the generator temperature is high. The maximum current for this unit is 7A, down from 10A and 12A for older models. As a leading ultrasonic equipment manufacturer, Kaijo is committed to continuously improving their ultrasonic cleaning system components and the company works to bring the most advanced and cost-effective ultrasonic cleaning solutions to their growing international customer base.