Selecting an Ultrasonic Transducer for Different Cleaning Applications

July 17, 2018

Ultrasonic cleaning systems are composed of a signal generator, an ultrasonic transducer and a cleaning tank. The transducer changes the electrical high-frequency signal from the generator into ultrasonic sound waves in the cleaning solution. Due to this key role, it is important to choose a transducer that will work well with the generator and cleaning tank but also perform as expected for the cleaning application.

Ultrasonic cleaning systems are composed of a signal generator, an ultrasonic transducer and a cleaning tank. The transducer changes the electrical high-frequency signal from the generator into ultrasonic sound waves in the cleaning solution. Due to this key role, it is important to choose a transducer that will work well with the generator and cleaning tank but also perform as expected for the cleaning application.

Ultrasonic Cleaning transducers have to deliver ultrasonic power in the liquid of the cleaning tank and withstand difficult operating environments without failure or reduced performance. Different types are available and some may be more suitable for specific cleaning tasks. Getting the best transducer means selecting the right type, designed by an experienced manufacturer and built with high-quality materials.

How an Ultrasonic Transducer Works

Kaijo’s ultrasonic cleaning transducers are made up of an electrical section that receives the electric signal from the ultrasonic generator and a mechanical section that vibrates at high frequency to generate the sound waves in the cleaning solution. Once received, the electric signal is applied across piezoelectric crystals that change the signal into vibrations. A heavy metal sheet is attached to the crystals and amplifies the vibration over a larger area. The whole construction is enclosed in a stainless-steel housing with the vibrations transmitted through the steel to the outside. When the transducer is immersed in the cleaning solution, the vibrations result in corresponding ultrasonic waves in the liquid.

Sound waves are compression waves that travel through the liquid as compression peaks and troughs. In the troughs, cavitation bubbles form due to the low pressure, and the bubbles collapse again in the high-pressure peaks. The collapsing bubbles release an energetic jet of cleaning solution that dislodges dirt and contaminants from the surface of the parts. The scrubbing action of these jets results in effective and rapid cleaning of the parts without damaging the underlying surface. Cleaning is thorough and takes place even in places that are inaccessible for conventional cleaning methods.

Type of Transducers

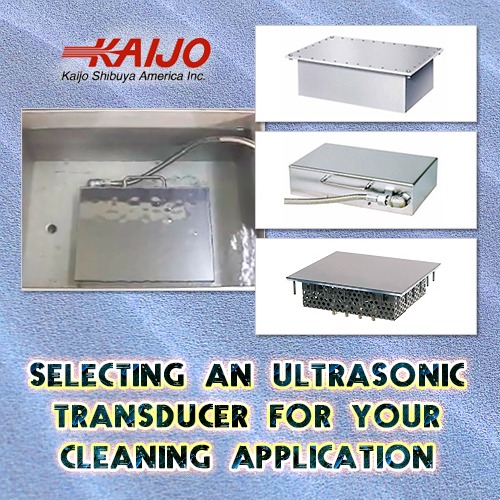

Different types of ultrasonic cleaning transducers are suitable for different cleaning applications. Kaijo offers immersible transducers, bolt-on transducers or mounted units depending on the cleaning system configuration. The transducers can be purchased separately, as individual units, or as part of a turnkey system.

Immersible transducers are the most flexible. They can be placed in any tank in the cleaning solution and will work whether they are horizontal or vertical, as long as they are completely immersed. These transducers are ideal for installing in an existing tank or an existing cleaning system for which ultrasonic cleaning is being added.

Bolt-on or mounted transducers are more permanently installed and can be part of a new system. The transducers are mounted or bolted onto the walls or bottom of the cleaning tank. For large tanks, several transducers may be needed to evenly fill the tank with ultrasonic waves.

Ultrasonic Transducer Characteristics

Ultrasonic transducers have to withstand the conditions present in the cleaning solution without damage. This means their surfaces have to be immune to pitting from exposure to ultrasonic waves and the housing must be waterproof. Ultrasonic cleaning solutions are sometimes heated and they may contain mild solvents. Transducers should continue to deliver rated performance under such operating conditions.

Kaijo has a complete line of ultrasonic transducers to meet the most demanding industrial cleaning requirements. Typical is the 40 kHz ultrasonic transducer, which will deliver 600 W or 1200 W of power, operate in up to 100 degrees centigrade liquids and which comes in a rugged hermetically sealed 316L stainless steel housing. Kaijo can help customers with their selection of ultrasonic transducers based on the company’s long-standing expertise in the ultrasonic cleaning field and can follow up recommendations with offers from their full line of transducers.