What Electronics Can You Clean in an Ultrasonic Cleaner?

September 12, 2022

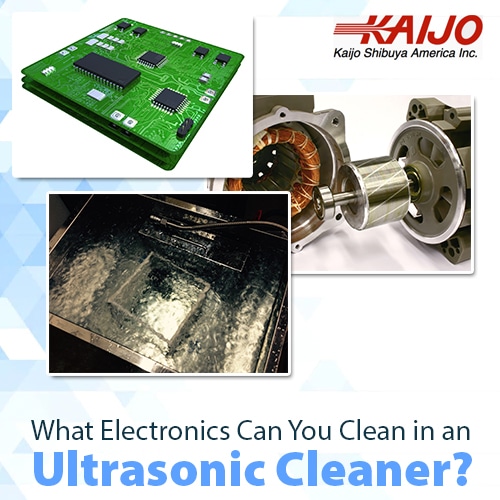

You can clean most types of electronics with an ultrasonic cleaner, but there are a few restrictions. Electronics that can be cleaned in an ultrasonic bath include circuit boards, electronic instruments, many electronic devices, and electronic components. Some need cleaning during the manufacturing process. Others must be cleaned because they gather dust and dirt that could reduce the useful life of the equipment. Industrial electronic instruments may have to be cleaned after every use to avoid contamination of the manufacturing process, and medical devices must be cleaned and sterilized.

You can clean most types of electronics with an ultrasonic cleaner, but there are a few restrictions. Electronics that can be cleaned in an ultrasonic bath include circuit boards, electronic instruments, many electronic devices, and electronic components. Some need cleaning during the manufacturing process. Others must be cleaned because they gather dust and dirt that could reduce the useful life of the equipment. Industrial electronic instruments may have to be cleaned after every use to avoid contamination of the manufacturing process, and medical devices must be cleaned and sterilized.

Ultrasonic cleaning is especially useful when surfaces are rough or when there are openings, holes, and crevices in the parts that need to be cleaned. Because ultrasonic cleaners can work with plain water, there is no risk of having cleaning chemicals leave a conducting residue that could cause the electronics to malfunction. The operator can adjust the intensity of the ultrasonic cleaning action to ensure delicate components are not damaged and soft films are cleaned gently. Ultrasonic cleaners can clean more quickly than traditional cleaning methods while respecting the correct procedures and the limitations of the cleaning process.

What to Watch for When Cleaning Electronics

Ultrasonic cleaning relies on immersion of the parts to be cleaned in water or in a mild cleaning solution in ultrasonic cleaning tanks. Electricity and water generally don’t mix, but you can clean electronics in a water bath. Of course, you will have to disconnect from their power source and dry them out entirely once they are clean. Electronics containing components that may be damaged by water, such as LCD or LED screens, should not be cleaned with ultrasonics unless you remove the sensitive components first.

Most electronics can be cleaned at a common ultrasonic frequency, such as 40 kHz, without damage from the ultrasonic cleaning action. Parts with very soft components, such as silicone seals or soft plastic, and parts with delicate coatings, paint, or plating may require higher frequencies. The cavitation bubbles responsible for the ultrasonic cleaning action are smaller at higher frequencies, and the cleaning is less intense. An experienced ultrasonic cleaning systems manufacturer can help choose the right frequency for cleaning the parts.

How to Clean Electronics Using an Ultrasonic Cleaner

Many electronic devices can be cleaned with ultrasonic cleaners without any problem. Following the steps below ensures that your parts can be cleaned and dried safely.

1. Make sure items are disconnected from their power source. Unplug items from wall sockets and take out all batteries.

2. Disassemble the major components to make drying easier. Internal spaces may collect water that will take a long time to dry.

3. Use a basket and screen to clean small parts in the ultrasonic cleaner. Place the clean parts into containers to avoid losing any.

4. Clean the large parts in the ultrasonic cleaner bath with clean water. Cleaning time depends on the contamination, typically around ten to twenty minutes.

5. Use a blower or a compressed air cleaner to blow excess moisture off the parts.

6. Place all parts in a drying chamber heated to 115 to 130 degrees Fahrenheit until completely dry, typically 6 to 8 hours.

7. Oil and grease parts as needed because the oil and grease are removed by ultrasonic cleaning.

8. Re-assemble the items and test them to ensure they work correctly.

The most important instructions to remember are that any parts cleaned may not have any electric power connected during cleaning. Also, everything must be completely dry before an item is tested.

Kaijo has extensive experience in ultrasonic cleaning technology. We can help select an ultrasonic cleaner suitable for an electronics cleaning application. When the right system and frequency are used, ultrasonic cleaning performance is superior to other cleaning methods. Contact Kaijo for a free consultation to discuss your specific cleaning application.